Roller material

Roller material

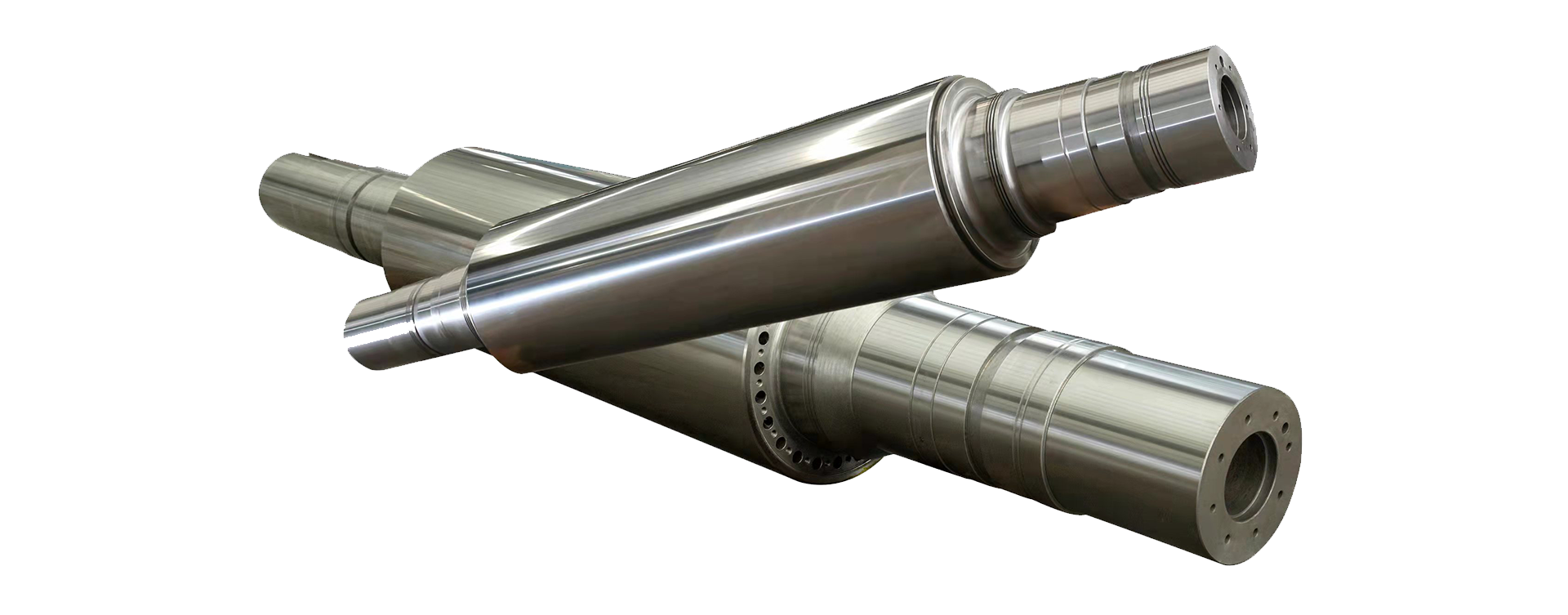

Rolls are key tools in industrial production such as metal processing and plastic processing. The choice of their materials directly determines the performance and service life of the rolls. The following is a detailed introduction to the roll material:

1. Basic overview

Roll material is mainly selected based on rolling materials, process requirements, working environment and other factors. Common roll materials include alloy forged steel, alloy cast steel, cast iron (such as ordinary cast iron, alloy cast iron and ductileiron) and cemented carbide. Each of these materials has its own characteristics and is suitable for different rolling processes and application scenarios.

2. Alloy forged steel

Alloy forged steel rolls have high strength and toughness and are suitable for rolling processes that withstand greater pressure and impact. Depending on the rolling process, alloy forged steel rolls can be made of different steel types, such as 55Mn2, 55Cr, 60CrMnMo, etc. commonly used for hot rolling rolls, and 9Cr, 9Cr2, 9CrV, etc. commonly used for cold rolling rolls.

3. Alloy cast steel

Alloy cast steel rolls have better wear resistance and compressive strength due to the denser structure formed during the casting process. With the development of electroslag remelting technology, the quality of alloy cast steel rolls has gradually improved and is expected to be more widely used in the future.

4. Cast iron rollers

Cast iron rolls include ordinary cast iron rolls, alloy cast iron rolls and ductile iron rolls. Cast iron rolls have high hardness and wear resistance, smooth surface, simple manufacturing process and low cost. Among them, ductile iron rolls have high strength and toughness and are suitable for rolling processes that bear heavy loads. Infinitely chilled cast iron roll is a special cast iron roll. The matrix structure of the working layer of the roll body contains more carbides and evenly distributed graphite, and has good wear resistance and thermal stability. Infinite chilled cast iron rolls are suitable for rolling scenarios with high process requirements such as hot rolled strips and medium and heavy plates.

5. Carbide

Cemented carbide is a new alloy mixed with high-hardness materials such as tungsten carbide and titanium carbide and high-toughness materials such as cobalt and nickel. Carbide rolls have excellent wear resistance, corrosion resistance and deformation resistance, and are especially suitable for rolling environments with high strength, high temperature and high friction. For example, in metal processing, plastic processing and other industries, carbide rolls can effectively resist wear, corrosion and deformation, improving rolling accuracy and product quality.

6. Summary

To sum up, the selection of roll material should be comprehensively considered based on rolling materials, process requirements, working environment and other factors. Materials such as alloy forged steel, alloy cast steel, cast iron and cemented carbide have their own characteristics and are suitable for different rolling processes and application scenarios. In actual production, appropriate roll materials should be selected according to specific conditions to improve rolling efficiency, reduce costs and extend the service life of the rolls.